The Burnham Series 2 Gas Boiler Manual provides essential guidance for installing‚ operating‚ and maintaining the boiler‚ ensuring safe and efficient performance while adhering to industry standards.

1.1 Overview of the Burnham Series 2 Gas Boiler

The Burnham Series 2 Gas Boiler is a high-efficiency‚ cast iron gas-fired boiler designed for residential and light commercial applications. Known for its durability and reliable performance‚ it features a robust cast iron construction that ensures long-lasting heat retention and energy efficiency. Equipped with an advanced gas control valve‚ the Series 2 offers precise combustion control‚ enhancing safety and operational efficiency. Its compact design and versatile installation options make it a popular choice for various heating needs.

1.2 Importance of the Manual for Installation and Operation

The Burnham Series 2 Gas Boiler manual is crucial for proper installation and operation. It provides detailed instructions‚ safety guidelines‚ and technical specifications to ensure the boiler functions efficiently and safely. Adhering to the manual minimizes risks of malfunction‚ enhances performance‚ and prolongs the boiler’s lifespan. It is essential reading for installers and users to understand system requirements and maintenance needs‚ ensuring compliance with industry standards and optimal energy use.

Key Features of the Burnham Series 2 Gas Boiler

The Burnham Series 2 Gas Boiler features advanced gas control valve technology‚ robust cast iron construction for durability‚ and high efficiency with AFUE ratings. It offers flexible venting options‚ including direct vent and power venting‚ and a compact design for versatile installation. The boiler incorporates energy-saving modulating burners‚ quiet operation‚ and comprehensive safety features. Available in various sizes‚ it ensures reliable heating performance for different home sizes‚ supported by a strong warranty and customer service.

2.1 Design and Construction of the Boiler

The Burnham Series 2 Gas Boiler features a robust cast iron construction‚ known for its durability and heat retention. Its compact design allows for easy installation in various spaces. The boiler is equipped with advanced heat exchangers for efficient heat transfer. Additionally‚ it incorporates a draft hood and vent damper for safe venting. The design ensures reliability and long-lasting performance‚ making it a popular choice for residential heating needs‚ while adhering to industry safety standards.

2.2 Advanced Gas Control Valve Technology

The Burnham Series 2 incorporates an advanced gas control valve‚ designed to optimize combustion efficiency and safety. This valve ensures precise gas flow regulation‚ reducing energy waste and enhancing performance. It also provides redundancy‚ as highlighted in the manual‚ to maintain reliable operation. The technology integrates seamlessly with the boiler’s vent damper system‚ promoting safe and efficient combustion. This feature simplifies maintenance and ensures compliance with industry safety standards‚ making it a key component of the boiler’s reliable operation and performance.

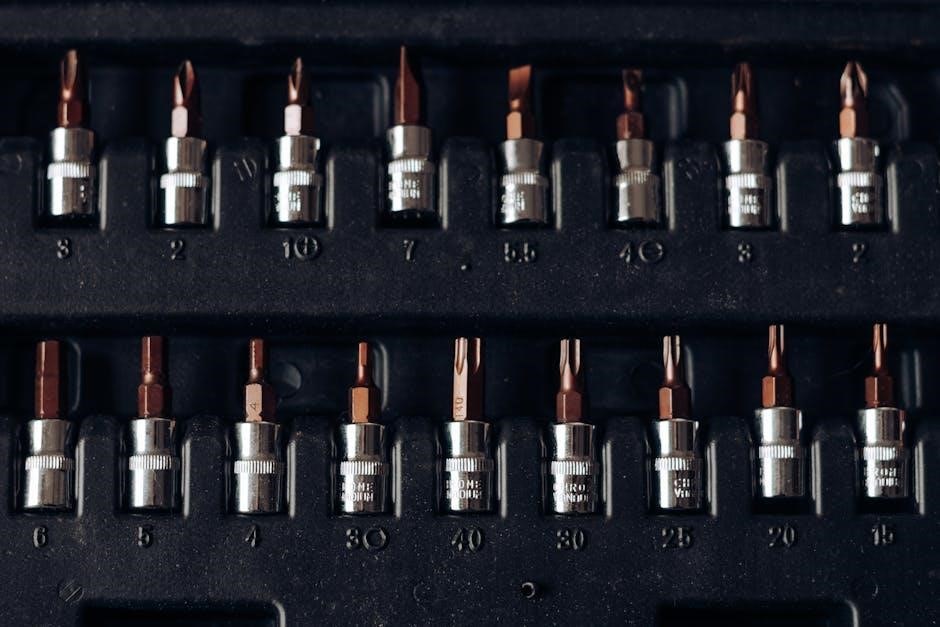

Installation Instructions for the Burnham Series 2 Gas Boiler

Install a sediment trap‚ ground-joint union‚ and manual shut-off valve upstream of the boiler’s gas control valve‚ ensuring compliance with safety and technical specifications outlined in the manual.

3.1 Pre-Installation Checks and Requirements

Before installing the Burnham Series 2 Gas Boiler‚ ensure the site meets all safety and technical requirements. Verify proper ventilation‚ gas supply lines‚ and electrical connections. Install a sediment trap‚ ground-joint union‚ and manual shut-off valve upstream of the boiler’s gas control valve. Ensure compliance with local codes and manufacturer guidelines to guarantee safe and efficient operation. Conduct a thorough inspection of all components for damage or defects prior to installation.

3.2 Step-by-Step Installation Process

Begin by unpacking and inspecting the boiler for damage. Place the boiler on a level surface‚ ensuring proper clearance for ventilation and maintenance. Connect the gas and electrical supply lines‚ adhering to local codes. Install the venting system according to the manufacturer’s specifications‚ using Type B or Type L vents. Connect the water supply lines and ensure all valves are correctly configured. Finally‚ test the system for leaks and proper functionality before initiating operation‚ referring to the manual for detailed guidance.

Operating Instructions for the Burnham Series 2 Gas Boiler

This section outlines the proper procedures for operating the Burnham Series 2 Gas Boiler‚ including start-up‚ monitoring‚ and daily maintenance to ensure efficiency and safety.

4.1 Initial Start-Up and Commissioning

Before starting the Burnham Series 2 Gas Boiler‚ ensure all connections are secure and components are properly installed. Begin by unpacking and inspecting the boiler for any damage; Connect gas‚ water‚ and electrical supplies according to the manual. Turn on the gas supply and verify the system for leaks. Power up the boiler and follow the ignition sequence. Monitor the burner flame and system pressure to ensure proper operation. Test all safety features and controls to confirm they function correctly. Record initial settings for future reference.

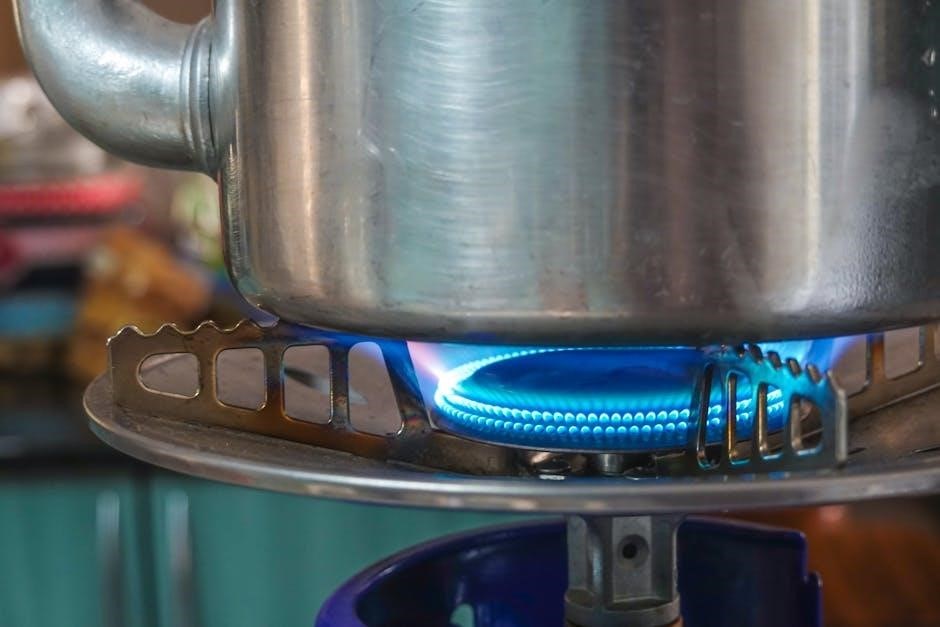

4.2 Daily Operation and Monitoring

Daily operation involves checking the gas supply‚ ensuring proper venting‚ and monitoring system pressure. Verify the burner flame is stable and blue‚ indicating correct combustion. Regularly inspect for leaks around connections and ensure all components function as intended. Use the advanced gas control valve to adjust settings if necessary. Monitor the boiler’s performance and maintain optimal water levels. Check the venting system for blockages and ensure the damper operates correctly. Keep the area around the boiler clean and well-ventilated for efficient operation.

Maintenance and Service Requirements

Regular maintenance ensures optimal performance and longevity. Check for leaks‚ clean components‚ and inspect gas valves. Schedule annual professional servicing to maintain efficiency and safety standards.

5.1 Scheduled Maintenance Tasks

Perform routine checks on the gas valve‚ vent system‚ and heat exchanger. Clean or replace air filters as needed. Inspect the boiler’s electrical connections and controls. Check for any leaks in the gas or water lines. Ensure the vent damper operates correctly. Schedule an annual professional inspection to maintain efficiency and safety. Keep the surrounding area clear of debris for proper airflow and combustion. Regular descaling of waterways may be required depending on water quality.

5.2 Troubleshooting Common Issues

Identify issues by observing symptoms like erratic heating‚ error codes‚ or unusual noises. Check the pilot light for proper ignition and ensure the gas supply is uninterrupted. Verify venting systems for blockages or leaks. Inspect electrical connections for looseness or damage. Refer to the manual for specific error code meanings and corrective actions. Address condensate drainage issues promptly to prevent system damage. If problems persist‚ consult a qualified technician to avoid safety risks or further complications.

Safety Precautions and Guidelines

Always ensure the gas supply is turned off during maintenance. Properly install venting systems to avoid gas leaks or carbon monoxide hazards. Keep the area well-ventilated and clear of flammable materials. Regularly inspect components like the vent damper and gas control valve for damage or blockages. Never attempt repairs without following safety protocols outlined in the manual. Ensure emergency shutdown procedures are understood and accessible.

6.1 General Safety Measures

Always adhere to safety guidelines when handling the Burnham Series 2 Gas Boiler. Ensure the gas supply is turned off before maintenance. Properly install venting systems to prevent gas leaks or carbon monoxide risks. Keep the boiler area clean and free from flammable materials. Regularly inspect components like the vent damper and gas control valve for damage or blockages. Never bypass safety devices or attempt repairs without proper training. Ensure all emergency shutdown procedures are easily accessible and understood.

6.2 Emergency Shutdown Procedures

In case of an emergency‚ immediately turn off the gas supply and power to the boiler. Close the manual shut-off valve located upstream of the gas control valve. Activate the emergency switch to halt operation. Ensure the boiler is isolated from the system and ventilate the area if gas is suspected. Do not attempt to restart the boiler until a qualified technician has inspected and cleared it for safe operation. Always follow manufacturer guidelines.

Technical Specifications of the Burnham Series 2 Gas Boiler

The Burnham Series 2 offers efficient performance with cast-iron construction‚ advanced gas valve technology‚ and compliance with industry standards‚ ensuring reliable and safe heating solutions.

7.1 Boiler Ratings and Performance

The Burnham Series 2 Gas Boiler is highly efficient‚ with an AFUE rating of up to 84%‚ ensuring optimal energy use. Its cast-iron construction and advanced heat exchanger design maximize durability and heat transfer. The boiler operates efficiently across a wide range of heating demands‚ making it suitable for various residential and light commercial applications. The Series 2 also features a high-performance gas valve‚ enabling precise combustion control and consistent heating performance. Its venting options‚ including draft hood and direct vent systems‚ further enhance flexibility and installation ease.

7.2 Compliance with Industry Standards

The Burnham Series 2 Gas Boiler meets rigorous industry standards‚ including ASHRAE 90.1b and Energy Star certification‚ ensuring energy efficiency and environmental compliance. It adheres to CSA and UL safety certifications‚ guaranteeing reliable operation. The boiler’s emissions comply with local and national regulations‚ and its design aligns with venting and installation guidelines set by industry experts. This compliance ensures safe‚ efficient‚ and environmentally responsible performance‚ meeting the demands of modern heating systems.

Accessories and Optional Components

The Burnham Series 2 Gas Boiler offers optional components like the System Bypass Circulator Kit and advanced venting systems‚ enhancing efficiency and customization for specific installations.

8.1 System Bypass Circulator Kit

The System Bypass Circulator Kit is designed to optimize hydronic system performance‚ ensuring consistent water flow and temperature. It works seamlessly with the Burnham Series 2 boiler‚ enhancing efficiency by maintaining proper circulation. This kit is recommended for systems requiring precise flow control and is easy to integrate‚ offering reliability and durability. Proper installation following the manual ensures optimal functionality and system longevity.

8.2 Venting and Damper Systems

Venting and damper systems are critical for proper combustion and safety in the Burnham Series 2 boiler. The boiler requires a Type B or Type L gas vent‚ installed according to manufacturer guidelines. The vent damper ensures efficient operation by regulating airflow. Proper installation‚ as detailed in the manual‚ is essential to prevent gas leaks and maintain performance. Always follow the manual’s instructions for venting to ensure compliance with safety standards and optimal boiler functionality.

The Burnham Series 2 Gas Boiler Manual ensures optimal performance and safety. Adhering to its guidelines guarantees efficient operation‚ longevity‚ and compliance with industry standards for years.

9.1 Summary of Key Points

The Burnham Series 2 Gas Boiler Manual provides comprehensive guidance for installation‚ operation‚ and maintenance. It emphasizes safety‚ efficiency‚ and durability‚ adhering to industry standards. The manual offers detailed instructions for initial setup‚ daily monitoring‚ and troubleshooting‚ ensuring optimal performance. By following the guidelines‚ users can maximize the boiler’s potential‚ achieving reliable and efficient heating solutions for years to come. Adherence to the manual is crucial for maintaining safety and operational excellence.

9.2 Final Tips for Optimal Boiler Performance

Regular maintenance is crucial for extending the boiler’s lifespan. Ensure annual professional inspections and cleanings. Always follow the manual’s guidelines for installation and operation. Monitor gas pressure and venting systems regularly to prevent issues. Keep the surrounding area clear of obstructions for proper airflow. Address any leaks or unusual noises promptly. By adhering to these tips‚ you can ensure efficient‚ safe‚ and reliable performance from your Burnham Series 2 Gas Boiler for years to come.