An overhead crane inspection checklist ensures the safety and efficiency of crane operations by systematically evaluating critical components. It helps prevent failures and ensures compliance with regulations.

Overview of Overhead Cranes and Their Importance in Industrial Operations

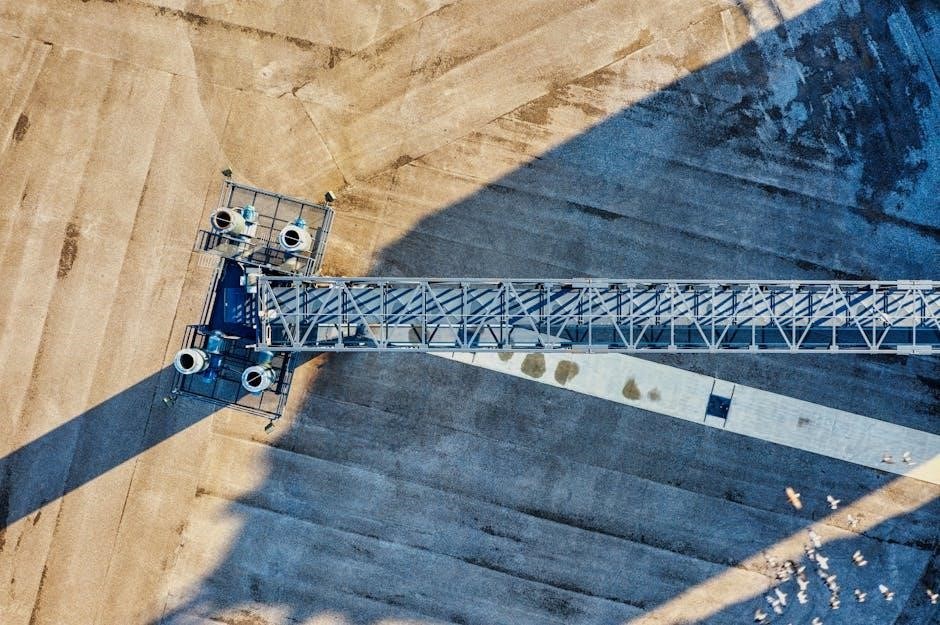

Overhead cranes are essential in industrial settings, enabling the safe and efficient movement of heavy loads across facilities. They are widely used in manufacturing, construction, and logistics, playing a critical role in streamlining operations. These cranes consist of a bridge, hoist, and trolley, designed to handle varying load capacities. Their versatility allows customization for specific industries, ensuring optimal performance. By minimizing manual labor and enhancing precision, overhead cranes significantly improve productivity. Regular inspections are vital to maintain their functionality and safety, ensuring uninterrupted workflow and operational reliability. Their importance lies in their ability to support complex industrial processes, making them indispensable assets in modern manufacturing environments.

Why Regular Inspections Are Crucial

Regular inspections are essential for ensuring the safety, reliability, and longevity of overhead cranes. They help identify potential hazards, prevent accidents, and maintain compliance with regulations.

Safety Compliance and Regulatory Requirements

Regular overhead crane inspections are mandated by regulations like OSHA Section 1910.179 and WAC 296-24-23519 to ensure operational safety and legal compliance. These standards require daily, weekly, and annual inspections to identify hazards and prevent accidents. Non-compliance can result in fines, operational shutdowns, and increased workplace risks. Inspection checklists must be documented, detailing findings and actions taken. Critical components like wire ropes, load chains, and braking systems must be thoroughly checked. Adhering to these regulations ensures a safe working environment, protects employees, and maintains operational integrity. Proper documentation also serves as proof of compliance during audits or incidents. Regular inspections are not just a legal obligation but a vital safety measure.

Preventing Equipment Failure and Ensuring Operational Efficiency

Regular inspections of overhead cranes are essential for preventing equipment failure and maintaining operational efficiency. By identifying and addressing issues early, such as worn wire ropes or faulty braking systems, downtime can be minimized. A comprehensive checklist ensures that all critical components, including hoist mechanisms and trolley systems, are functioning properly. Early detection of potential problems allows for timely repairs, reducing the risk of costly breakdowns. This proactive approach not only extends the lifespan of the crane but also ensures smooth production processes. Efficient operations are achieved when all components are in optimal working condition, making regular inspections a cornerstone of equipment maintenance and reliability.

Understanding the Overhead Crane Inspection Checklist

The checklist outlines essential steps to evaluate crane components, ensuring safe operation and compliance. It covers daily, weekly, and annual inspections for optimal maintenance and functionality.

Daily Pre-Operational Checks

Daily pre-operational checks are essential to ensure the crane’s safe and efficient operation. Operators should inspect the hoist, trolley, and bridge for proper alignment and function. Wire ropes and load chains must be examined for wear, tear, or corrosion. Braking systems should be tested to confirm they engage correctly. Lubrication levels and electrical connections should also be verified. Operators must check for any visible damage or malfunctions, such as loose bolts or worn components. Functional tests, like raising and lowering the load, should be performed to ensure smooth operation. Any defects found must be documented and addressed promptly to prevent accidents and maintain compliance with safety standards.

Weekly and Monthly Maintenance Inspections

Weekly and monthly inspections are crucial for maintaining the crane’s optimal performance and safety. These inspections involve a more detailed examination of components compared to daily checks. Operators should inspect wire ropes for signs of wear, such as corrosion or strand breaks, and ensure proper lubrication. Brake systems must be tested for reliability, and electrical components, like contactors and limit switches, should be checked for functionality. Monthly inspections may include verifying the alignment of the bridge and runway, checking for excessive wear on trolley wheels, and ensuring all safety devices are operational. These regular maintenance checks help prevent unexpected equipment failures and extend the crane’s service life.

Annual Comprehensive Inspections

Annual comprehensive inspections are the most thorough and detailed evaluations of an overhead crane’s condition. These inspections are typically performed by qualified professionals and cover all critical components, including wire ropes, load chains, hoist mechanisms, and structural elements. Non-destructive testing methods may be employed to identify hidden defects. The crane’s braking systems, motor performance, and electrical connections are also thoroughly examined. Additionally, the alignment of the bridge and runway is verified, and load-testing is conducted to ensure the crane can safely handle its maximum capacity. Documentation of findings is essential, and any defects must be addressed promptly to maintain safety and compliance with regulatory standards like OSHA 1910.179.

Key Components to Inspect

Critical components include the hoist and trolley mechanisms, bridge and runway structures, wire ropes, load chains, and braking systems. These ensure safe and efficient crane operation.

Hoist and Trolley Mechanisms

The hoist and trolley mechanisms are essential for lifting and moving loads. During inspections, check for wear on gears and bearings, proper alignment, and smooth operation. Ensure wire ropes are free from damage and load chains are intact. Lubricate moving parts regularly. Examine brakes and control systems for functionality. Any malfunctions should be documented and addressed promptly to prevent accidents. Regular maintenance extends equipment life and ensures reliable performance. Proper functioning of these components is crucial for safe crane operation. Always refer to the inspection checklist for detailed evaluation steps.

Bridge and Runway Structures

The bridge and runway structures are critical components of an overhead crane system. Regular inspections ensure their stability and alignment. Check the bridge girders, end trucks, and connections for cracks, corrosion, or loose bolts. Inspect the runway beams and support brackets for proper alignment and secure fastening. Ensure all welds are intact and free from defects. Lubricate moving parts like wheels and bearings as needed. Examine bumpers and stops for damage or wear. Verify that the bridge and runway are level and properly aligned. Document any issues and address them promptly to maintain structural integrity and prevent operational hazards. Proper maintenance ensures safe and efficient crane operation.

Wire Ropes and Load Chains

Wire ropes and load chains are essential for lifting and moving loads safely. Inspect wire ropes for signs of wear, corrosion, or damage, such as frayed strands or broken wires. Check for proper lubrication and ensure the rope is not kinked or twisted. For load chains, examine each link for cracks, corrosion, or excessive wear. Measure chain stretch to ensure it is within acceptable limits. Look for any signs of deformation or damage from overloading. Replace any damaged or worn components immediately to prevent failure during operation. Regular lubrication and thorough inspection ensure the longevity and reliability of these critical lifting components. Always follow manufacturer guidelines for maintenance and replacement. Proper care ensures safe and efficient load handling.

Braking Systems and Controls

Braking systems and controls are critical for safe crane operation, ensuring precise load control and emergency stopping. Inspect brake pads for wear, alignment, and proper engagement. Check air gaps between pads and drums, ensuring they meet manufacturer specifications. Look for corrosion or damage on brake components, which can compromise braking efficiency. Test the brakes under load to confirm smooth, consistent stopping without jerking. Verify that all control levers and joysticks function correctly, with no excessive play or sticking. Ensure emergency stop buttons are easily accessible and functioning properly. Regularly lubricate moving parts to prevent wear. Any defects in braking systems or controls must be addressed immediately to prevent accidents and maintain operational safety. Adhere to OSHA guidelines for inspection and maintenance.

Documenting Inspection Findings

Accurate and detailed documentation of inspection findings ensures accountability and traceability. Record all observations, noting compliance status, defects, and required repairs. Maintain records for future reference.

Importance of Record-Keeping

Record-keeping is essential for maintaining accountability and ensuring compliance with safety standards. Detailed documentation of inspections provides a historical record, aiding in tracking equipment condition over time. This data is crucial for identifying trends, planning maintenance, and demonstrating adherence to regulatory requirements. Proper records also facilitate audits and legal compliance, safeguarding against potential liabilities. By maintaining accurate and organized records, organizations can ensure continuous operational safety and efficiency. Regular audits of these records help verify the effectiveness of the inspection program and highlight areas for improvement. Thus, record-keeping is a cornerstone of a robust overhead crane inspection process.

Actions to Take in Case of Defects or Malfunctions

Upon identifying defects or malfunctions during an inspection, immediate action is required to ensure safety and prevent further damage. First, operations should be suspended, and the crane must be isolated from use until repairs are made.notify supervisors and maintenance personnel to address the issue promptly. All defects must be documented in the inspection record, detailing the nature of the problem and the corrective actions needed. Critical issues may require external expertise or specialized tools to resolve. Once repairs are completed, a follow-up inspection is necessary to confirm the crane’s safe operation before returning it to service. This systematic approach ensures compliance with safety standards and maintains operational integrity.

Regular inspections using an overhead crane inspection checklist are vital for ensuring safety, compliance, and operational efficiency, helping to prevent accidents and extend equipment lifespan.

Adhering to a structured overhead crane inspection checklist ensures compliance with safety standards and prevents operational hazards. Conduct daily, weekly, and monthly inspections, focusing on critical components like wire ropes, hoists, and braking systems. Document all findings and address defects promptly to maintain efficiency and safety. Regular lubrication of moving parts and thorough examination of load chains and hooks are essential. Training operators and inspectors on OSHA regulations and inspection procedures is crucial for accurate evaluations. Implementing a preventive maintenance schedule helps extend equipment lifespan and avoid unexpected failures. A well-executed inspection plan safeguards both personnel and equipment, ensuring smooth industrial operations. Always refer to updated guidelines for comprehensive checks.