Technical drawing, often referred to as engineering graphics, is a precise and systematic method of conveying engineering concepts and designs through visual representations․ It serves as a universal language for engineers, architects, and technicians to communicate ideas, plans, and specifications with clarity and accuracy․ This discipline combines art and science, requiring both creativity and adherence to established standards and conventions․

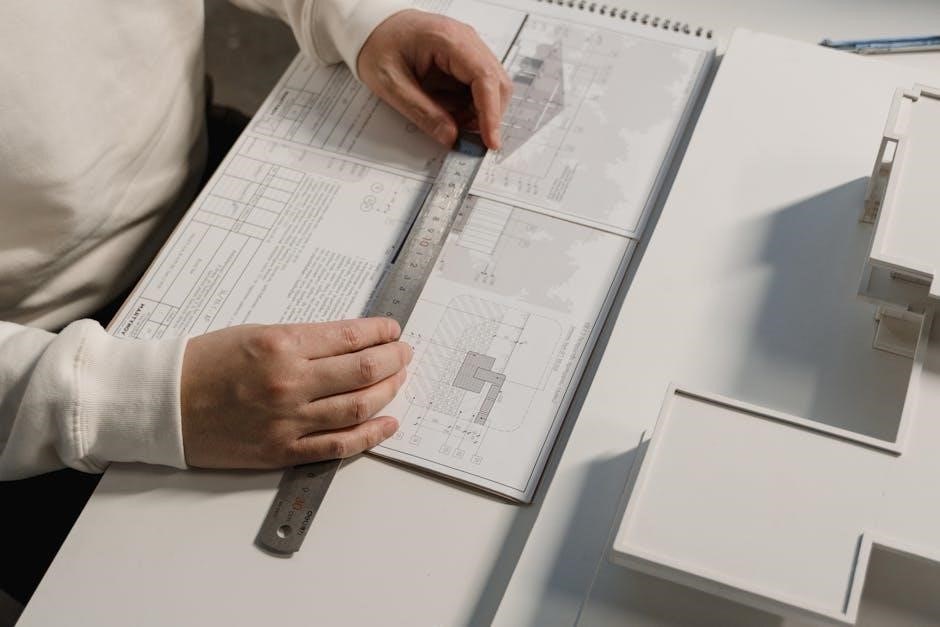

Engineering graphics involves the use of various tools and techniques to create detailed and scaled drawings of objects, mechanisms, and systems․ These drawings are essential for the design, development, and manufacturing processes․ Whether manually drafted or created using computer-aided design (CAD) software, technical drawings provide a common framework for understanding complex engineering problems and solutions․

The foundation of technical drawing lies in understanding fundamental principles such as perspective, projection, and dimensioning․ Different types of projections, like orthographic and axonometric, are used to represent three-dimensional objects in a two-dimensional format․ Standardized symbols, notations, and scales ensure consistency and readability across different industries and regions․

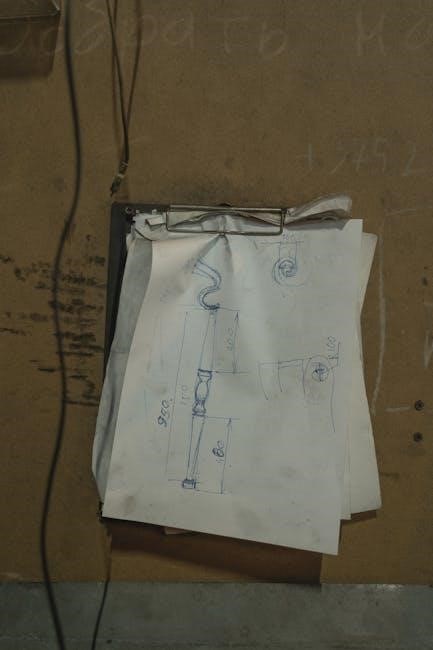

Technical drawing is not only a tool for documentation but also a means of analysis and innovation․ By visualizing ideas and concepts, engineers can identify potential flaws, explore alternatives, and refine designs before moving to production․ This makes it an indispensable skill in fields like mechanical engineering, architecture, and product design․

Understanding the basics of technical drawing is essential for anyone pursuing a career in engineering or related disciplines․ It provides the skills to interpret and create drawings, ensuring seamless collaboration and accurate execution of projects․

Importance of Technical Drawing in Engineering

Technical drawing plays a pivotal role in the field of engineering, serving as a cornerstone for effective communication, design precision, and project execution․ Its significance extends across various engineering disciplines, including mechanical, civil, electrical, and aerospace engineering․ By providing a universal language, technical drawings bridge the gap between conceptual ideas and physical reality, ensuring that designs are understood and implemented accurately․

Clarity and Precision in Communication

One of the most critical aspects of technical drawing is its ability to convey complex ideas with clarity and precision․ Engineering projects often involve intricate details, and without a standardized method of representation, misunderstandings can arise, leading to costly errors․ Technical drawings eliminate ambiguity by using established symbols, notations, and scales, ensuring that all stakeholders—engineers, technicians, and manufacturers—interpret the design consistently․

For instance, in mechanical engineering, a detailed blueprint of a machine component includes dimensions, tolerances, and material specifications․ This level of detail ensures that the manufacturer can produce the part accurately, minimizing the risk of defects․ Similarly, in civil engineering, architectural drawings provide a clear roadmap for contractors, enabling them to construct buildings and infrastructure according to the designer’s vision․

Facilitating Design Analysis and Problem-Solving

Technical drawings are not just tools for documentation but also for design analysis and problem-solving․ By visualizing a design, engineers can identify potential flaws, test hypotheses, and explore alternative solutions․ This iterative process is essential in engineering, where optimizing performance, safety, and cost-efficiency is paramount․

For example, in aerospace engineering, technical drawings are used to analyze the structural integrity of aircraft components․ By studying the drawings, engineers can simulate stress loads, identify weak points, and make necessary adjustments before moving to prototyping․ This saves time and resources, as issues are resolved at the design stage rather than during production or testing․

Enabling Manufacturing and Construction

Technical drawings are the backbone of the manufacturing and construction industries․ They provide the detailed instructions necessary for transforming raw materials into finished products․ Whether it’s a simple mechanical component or a complex system, the drawing serves as a roadmap, guiding the fabrication process step by step․

In construction, technical drawings are used to plan and execute projects efficiently․ Architectural drawings show the layout of buildings, while structural drawings detail the framework, including beams, columns, and foundations․ Electrical and plumbing drawings provide the necessary information for installing systems within the building․ Without these drawings, construction teams would lack the guidance needed to complete projects accurately and safely․

Standardization and Consistency

Technical drawing relies on standardized conventions, ensuring consistency across different industries and regions․ Organizations such as the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO) have established guidelines for creating technical drawings․ These standards dictate everything from line types and symbols to dimensioning methods and tolerances․

Standardization is particularly important in global engineering projects, where teams from different countries collaborate․ A technical drawing created in one region can be easily understood and implemented in another, provided it adheres to recognized standards․ This consistency reduces errors and ensures that products meet international quality requirements․

Documentation and Record-Keeping

Technical drawings serve as permanent records of engineering projects, providing valuable documentation for future reference․ These records are essential for maintenance, repairs, and upgrades․ For example, a technical drawing of a power plant’s piping system allows maintenance crews to locate valves and understand the flow of materials, even years after the initial installation․

In addition, technical drawings are often required for compliance with regulatory and legal requirements․ In industries such as aerospace and automotive, detailed documentation is mandatory to ensure safety and adherence to industry standards․ These drawings can also serve as evidence in legal disputes, providing a clear record of the design intent and specifications․

Cost Savings and Efficiency

By enabling precise communication and reducing errors, technical drawings contribute to cost savings and increased efficiency in engineering projects․ Mistakes detected at the design stage are far cheaper to correct than those discovered during production or after a product has been released to the market․

For instance, in product design, a well-detailed technical drawing can help identify manufacturing constraints early on․ This allows designers to modify the design to suit production capabilities, reducing the need for costly retooling or redesigns․ Similarly, in construction, accurate drawings ensure that materials are used efficiently, minimizing waste and reducing project timelines․

Promoting Innovation and Creativity

Technical drawing is not only a practical tool but also a means of fostering innovation and creativity․ By allowing engineers to visualize and explore different design possibilities, technical drawings facilitate the development of new ideas and solutions․ This is particularly important in fields such as robotics and renewable energy, where innovation is driving rapid advancements․

The process of creating technical drawings encourages engineers to think critically about design parameters, such as functionality, aesthetics, and sustainability․ For example, in the design of a sustainable building, technical drawings can illustrate energy-efficient features, such as solar panels and green roofs, helping to communicate the environmental benefits of the design․

Enhancing Collaboration and Teamwork

Technical drawings are often created by teams of engineers, designers, and drafters working together to bring a project to life․ This collaborative process fosters teamwork and ensures that all aspects of the design are considered․ By providing a shared visual language, technical drawings help team members align their efforts and work toward a common goal․

In global engineering projects, technical drawings often serve as the primary means of communication, bridging language and cultural barriers․ A well-prepared technical drawing can convey complex ideas more effectively than written or verbal instructions, ensuring that all team members are on the same page․

Supporting Legal and Contractual Requirements

In many industries, technical drawings are required to meet legal and contractual obligations․ For example, in construction, drawings must comply with building codes and zoning regulations․ Similarly, in product design, drawings must adhere to safety standards and industry specifications․

Technical drawings also play a role in contract negotiations and project bidding․ They provide a clear understanding of the scope of work, allowing clients and contractors to agree on deliverables and timelines․ This helps prevent disputes and ensures that projects are completed to the satisfaction of all parties involved․

Role in Education and Training

Technical drawing is a fundamental skill taught in engineering and technical education programs․ By learning to create and interpret technical drawings, students develop essential problem-solving and critical-thinking abilities․ These skills are invaluable in their future careers, enabling them to communicate ideas effectively and collaborate with colleagues․

In addition, technical drawing promotes spatial reasoning and visual literacy, which are critical for understanding complex engineering concepts․ For example, students studying mechanical engineering learn to interpret orthographic projections, enabling them to visualize and analyze three-dimensional